A pressure washer is an essential tool for cleaning various surfaces effectively. It combines high pressure with water to remove dirt, grime, and other debris. However, sometimes a pressure washer may not perform as expected and might show a significant drop in pressure. This can be frustrating and can hinder your cleaning tasks. Understanding the reasons behind this issue can help you troubleshoot and fix it efficiently. This article explores the common reasons why your pressure washer might have no pressure and provides practical solutions to restore its functionality.

Understanding How a Pressure Washer Works

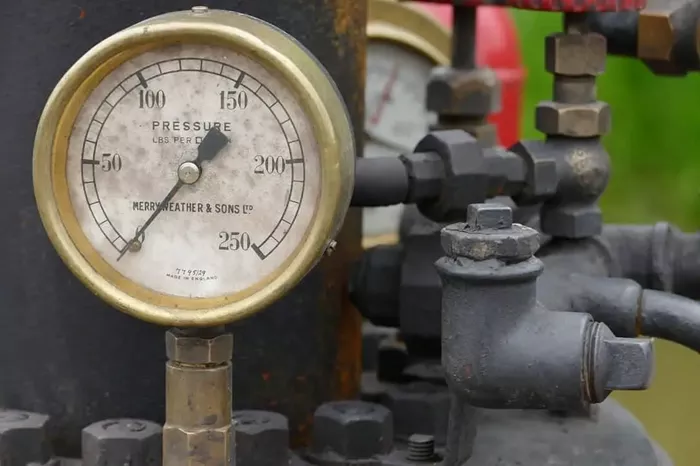

Before delving into the issues and solutions, it’s important to understand how a pressure washer works. A pressure washer consists of several key components: the water inlet, pump, engine (gas or electric), hose, and nozzle.

Water Inlet: This is where the water enters the pressure washer from a hose connected to your home’s water supply.

Pump: The pump is the heart of the pressure washer. It pressurizes the water, making it powerful enough to clean surfaces effectively.

Engine: The engine powers the pump. It can be either gas-powered or electric.

Hose: The high-pressure hose carries the pressurized water from the pump to the nozzle.

Nozzle: The nozzle controls the spray pattern and pressure of the water as it exits the hose.

If any of these components fail or malfunction, it can result in a loss of pressure. Let’s examine the common issues and their solutions.

Common Causes of No Pressure in Pressure Washers

1. Water Supply Issues

One of the most common reasons for a pressure washer to lose pressure is an inadequate water supply. This can be caused by several factors:

Clogged Water Inlet: Dirt, debris, and sediment can clog the water inlet, restricting the flow of water into the pressure washer.

Low Water Pressure from Source: If the water supply itself has low pressure, the pressure washer cannot build up the required pressure.

Kinked or Leaking Hose: A kinked or leaking hose can restrict water flow, leading to low pressure.

Solution: Check the water inlet for any clogs and clean it if necessary. Ensure that the water source provides sufficient pressure and there are no kinks or leaks in the hose.

2. Faulty Pump

The pump is a crucial component that pressurizes the water. If the pump is faulty, the pressure washer will not be able to build up pressure.

Worn Out Seals or Valves: The seals and valves inside the pump can wear out over time, leading to leaks and reduced pressure.

Damaged Pump Components: Any damage to the pump components, such as the pistons or plungers, can affect its performance.

Solution: Inspect the pump for any signs of wear and tear. Replace worn-out seals or valves and repair or replace any damaged components.

3. Air in the System

Air trapped in the pressure washer system can cause a significant drop in pressure. This can happen if the water supply is interrupted or if the washer has not been used for a while.

Solution: To remove air from the system, turn off the pressure washer and disconnect the hose. Reconnect the hose and turn on the water supply. Allow water to flow through the system until all the air bubbles are expelled. Then, turn on the pressure washer.

4. Dirty or Clogged Nozzle

The nozzle at the end of the pressure washer hose controls the spray pattern and pressure. If the nozzle is dirty or clogged, it can restrict water flow and reduce pressure.

Solution: Clean the nozzle with a small brush or a nozzle cleaning tool. Ensure that there are no obstructions and the nozzle is not damaged. If necessary, replace the nozzle.

5. Incorrect Nozzle Size

Using the wrong nozzle size can also affect the pressure. Each nozzle size is designed for a specific pressure range. Using a nozzle with a larger orifice can reduce the pressure.

Solution: Check the nozzle size and ensure it matches the specifications of your pressure washer. Refer to the user manual for the correct nozzle size.

6. Leaking Connections

Leaks in any of the connections can result in a loss of pressure. This includes connections between the hose and the pressure washer, as well as connections within the pump.

Solution: Inspect all connections for any signs of leaks. Tighten any loose connections and replace damaged O-rings or seals.

7. Faulty Unloader Valve

The unloader valve regulates the pressure within the pump. If the unloader valve is faulty, it can cause a loss of pressure.

Solution: Test the unloader valve by adjusting it. If adjusting the valve does not resolve the issue, replace the unloader valve.

8. Inadequate Power Supply

For electric pressure washers, an inadequate power supply can result in reduced pressure. This can be caused by a low voltage or an extension cord that is too long or thin.

Solution: Ensure that the pressure washer is plugged directly into a power outlet. Avoid using long or thin extension cords. Check the voltage of the power supply to ensure it meets the requirements of the pressure washer.

Detailed Troubleshooting Steps

To help you diagnose and fix the issue of no pressure in your pressure washer, here are detailed troubleshooting steps:

Step 1: Check the Water Supply

Inspect the Water Inlet: Remove the hose from the water inlet and check for any debris or sediment. Clean the inlet thoroughly.

Ensure Adequate Water Pressure: Check the water pressure from the source. It should be at least 20 PSI (pounds per square inch).

Inspect the Hose: Check the hose for any kinks, leaks, or damage. Replace the hose if necessary.

Step 2: Check the Pump

Inspect the Pump: Remove the pump cover and inspect the internal components for any signs of wear or damage.

Check the Seals and Valves: Inspect the seals and valves for any wear and tear. Replace them if they are worn out.

Test the Pump: Reassemble the pump and test it. If the pressure is still low, consider replacing the pump.

Step 3: Remove Air from the System

Turn Off the Pressure Washer: Turn off the pressure washer and disconnect the hose.

Reconnect the Hose: Reconnect the hose and turn on the water supply.

Expel Air Bubbles: Allow water to flow through the system until all air bubbles are expelled.

Turn On the Pressure Washer: Turn on the pressure washer and test the pressure.

Step 4: Clean or Replace the Nozzle

Inspect the Nozzle: Remove the nozzle and inspect it for any dirt or clogs.

Clean the Nozzle: Use a small brush or nozzle cleaning tool to clean the nozzle.

Replace the Nozzle: If the nozzle is damaged, replace it with a new one.

Step 5: Check for Leaks

Inspect All Connections: Inspect all connections for any signs of leaks.

Tighten Loose Connections: Tighten any loose connections.

Replace Damaged O-Rings or Seals: Replace any damaged O-rings or seals.

Step 6: Test the Unloader Valve

Adjust the Unloader Valve: Adjust the unloader valve and test the pressure.

Replace the Unloader Valve: If adjusting the valve does not resolve the issue, replace the unloader valve.

Step 7: Check the Power Supply (for Electric Pressure Washers)

Inspect the Power Cord: Ensure that the pressure washer is plugged directly into a power outlet.

Avoid Long Extension Cords: Avoid using long or thin extension cords.

Check the Voltage: Check the voltage of the power supply to ensure it meets the requirements of the pressure washer.

Preventive Maintenance Tips

Regular maintenance can help prevent issues with your pressure washer and ensure it operates at optimal performance. Here are some preventive maintenance tips:

1. Regularly Inspect and Clean the Water Inlet

Check the water inlet for any debris or sediment and clean it regularly.

2. Maintain the Pump

Inspect the pump regularly for any signs of wear or damage. Replace worn-out seals and valves as needed.

3. Check and Replace the Nozzle

Inspect the nozzle for any dirt or clogs. Clean or replace the nozzle regularly.

4. Inspect Hoses and Connections

Regularly inspect hoses and connections for any signs of wear, damage, or leaks. Replace damaged hoses and tighten loose connections.

5. Store Properly

Store the pressure washer in a dry and clean area. Protect it from extreme temperatures and direct sunlight.

6. Use the Correct Nozzle Size

Always use the correct nozzle size as specified in the user manual.

7. Follow the Manufacturer’s Instructions

Follow the manufacturer’s instructions for operation and maintenance to ensure the longevity and performance of your pressure washer.

Conclusion

A pressure washer with no pressure can be a frustrating issue, but it is often caused by common problems that can be easily fixed. By understanding the components of a pressure washer and following the troubleshooting steps outlined in this article, you can diagnose and resolve the issue effectively. Regular maintenance and proper usage can also help prevent such problems and ensure your pressure washer operates at its best. If the issue persists despite troubleshooting, it may be time to consult a professional or consider replacing the pressure washer.