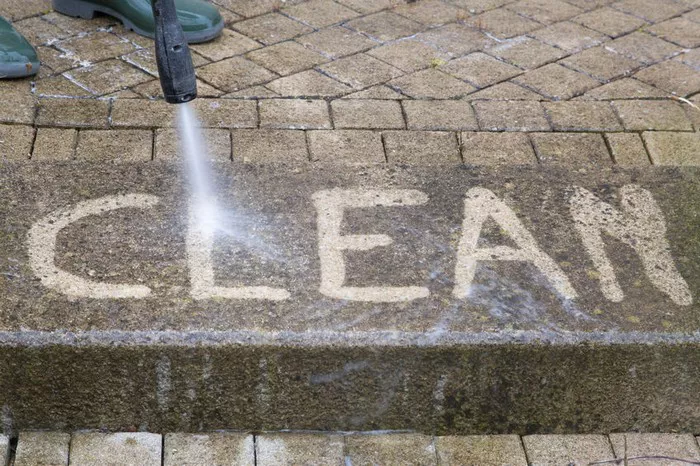

Pressure washers are versatile cleaning machines designed to deliver high-pressure water streams for various cleaning tasks. From washing vehicles to cleaning outdoor surfaces like driveways and patios, pressure washers offer efficiency and effectiveness in removing dirt, grime, and stains. Understanding how pressure washers work and their components is essential for maximizing their cleaning potential.

Brief Overview

A pressure washer consists of several key components that work together to generate high-pressure water. These machines are powered by either electric motors or gas engines, providing the necessary energy to operate the pump. The high-pressure water stream produced by pressure washers is highly effective in cleaning surfaces quickly and efficiently.

Importance of Pressure Washers

Pressure washers play a vital role in a wide range of cleaning tasks, both for residential and commercial purposes. Their ability to blast away dirt and grime with high-pressure water makes them indispensable tools for cleaning outdoor surfaces, vehicles, machinery, and more. Whether used for routine maintenance or tackling tough cleaning jobs, pressure washers offer unmatched cleaning power and efficiency.

Components of a Pressure Washer

Understanding the main parts of a pressure washer is crucial for knowing how these machines operate and how to maintain them properly.

Pump

The pump is the heart of a pressure washer, responsible for pressurizing water from the water source. It creates the high-pressure water stream that is emitted through the nozzle. Pumps in pressure washers can be either axial or triplex, with triplex pumps typically offering higher pressure and durability.

Engine or Motor

The engine or motor powers the pump, providing the energy needed to pressurize the water. Gas-powered pressure washers typically feature gasoline engines, while electric pressure washers are equipped with electric motors. The power output of the engine or motor directly influences the pressure and flow rate of the water.

Hose

The hose connects the pressure washer to the water source and the spray wand or gun. It transports water from the source to the pump and then delivers the pressurized water to the nozzle. High-quality hoses are essential for ensuring efficient water flow and minimizing the risk of leaks or bursts.

Wand or Gun

The spray wand or gun is the handheld component that users control to direct the high-pressure water stream onto the cleaning surface. It typically features a trigger for controlling the flow of water and may include attachments for different nozzle types.

Nozzles

Nozzles play a crucial role in determining the characteristics of the water stream emitted by the pressure washer. Different nozzle types produce varying spray patterns, such as narrow streams for high-pressure cleaning or wide sprays for gentle rinsing. Users can interchange nozzles to adjust the pressure and flow for different cleaning tasks.

Detergent Tank (if applicable)

Some pressure washers feature built-in detergent tanks for applying cleaning solutions to surfaces along with the high-pressure water. These tanks allow users to apply detergents, degreasers, or other cleaning agents to enhance the cleaning effectiveness of the pressure washer.

How Pressure Washers Generate Pressure

Pressure washers utilize a combination of water flow and pressure to achieve effective cleaning results. Understanding how these machines generate pressure is essential for optimizing their performance.

Pump Operation

The pump in a pressure washer pressurizes water by creating a flow restriction, forcing the water through a small orifice at high velocity. This restriction increases the pressure of the water, converting the kinetic energy of the flowing water into pressure energy. The pump then delivers the pressurized water through the hose and nozzle for cleaning.

Engine or Motor Function

The engine or motor of the pressure washer powers the pump, providing the necessary energy to create high pressure. Gas-powered pressure washers rely on gasoline engines, while electric pressure washers use electric motors. The power output of the engine or motor directly influences the pressure and flow rate of the water.

Water Supply and Inlet

Adequate water supply is essential for the efficient operation of a pressure washer. Properly connecting the pressure washer to a water source ensures a steady flow of water to the pump for pressurization.

Connection to Water Source

Pressure washers are typically connected to a standard garden hose for a water supply. Some models may require specific inlet fittings or adapters to connect to the water source securely. It’s essential to ensure that the water supply provides sufficient flow and pressure for the pressure washer to operate effectively.

Importance of Proper Water Supply

Insufficient water flow or pressure can impact the performance of the pressure washer, leading to reduced cleaning effectiveness or potential damage to the pump. Users should check and adjust the water supply as needed to ensure optimal performance during operation.

Adjusting Pressure and Flow

Pressure washers offer flexibility in adjusting pressure and flow settings to accommodate different cleaning tasks and surface types.

Pressure and Flow Adjustment

Users can adjust the pressure and flow settings on a pressure washer using the controls provided on the machine or the spray wand/gun. Lower pressure and higher flow rates are suitable for delicate surfaces or gentle rinsing, while higher pressure settings are effective for removing stubborn dirt and stains.

Nozzle Selection

The choice of nozzle also affects the pressure and flow characteristics of the water stream. Pressure washer nozzles are color-coded to indicate the spray pattern and angle, with narrower angles producing higher pressure. Users can select the appropriate nozzle based on the cleaning task and desired pressure level.

Safety Considerations

Safety should always be a top priority when operating a pressure washer to prevent accidents and injuries.

Proper PPE

Wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and closed-toe shoes, to protect against flying debris, chemical splashes, and high-pressure spray.

Avoiding Electrical Hazards

Take precautions to prevent electrical hazards when using electric pressure washers, such as using ground fault circuit interrupters (GFCIs) and keeping electrical cords away from water sources.

Using Appropriate Pressure and Nozzle Settings

Adjust the pressure and nozzle settings to match the cleaning task and surface type, avoiding excessive pressure that could cause damage or injury.

Preventing Injuries

Exercise caution when operating a pressure washer to avoid injuries from high-pressure spray. Keep the spray wand/gun pointed away from yourself and others, and never direct the spray at people, animals, or fragile objects.

Maintenance and Care

Regular maintenance is essential for keeping a pressure washer in good working condition and prolonging its lifespan.

Routine Maintenance Tasks

Perform routine maintenance tasks such as checking for leaks, inspecting hoses and connections, and cleaning or replacing filters as needed. Follow the manufacturer’s guidelines for maintenance intervals and procedures.

Storage and Winterization

Proper storage and winterization are crucial for preventing damage to the pressure washer during periods of non-use, especially in cold climates. Drain water from the pump, hoses, and spray wand/gun, and store the pressure washer in a dry, sheltered location away from freezing temperatures.

Common Issues and Troubleshooting

Despite proper maintenance, pressure washers may experience common problems that require troubleshooting and repair.

Loss of Pressure

Loss of pressure can result from various issues, such as clogged nozzles, air leaks, or pump problems. Troubleshoot the cause of the pressure loss and address any issues with cleaning, repairs, or replacement parts as needed.

Leaks

Leaks in hoses, connections, or the pump can reduce the effectiveness of the pressure washer and waste water. Inspect the pressure washer for leaks and repair or replace damaged components to prevent water loss and maintain optimal performance.

Engine Problems

Gas-powered pressure washers may experience engine-related issues such as starting difficulties, stalling, or lack of power. Follow the manufacturer’s recommendations for engine maintenance and troubleshooting, including checking fuel levels, spark plugs, and air filters.

Conclusion

Pressure washers are powerful cleaning tools that offer efficiency and effectiveness in a wide range of cleaning tasks. By understanding how pressure washers work and following safety guidelines, users can harness the cleaning power of these machines to tackle tough dirt and grime effectively and safely. Regular maintenance and proper care are essential for keeping pressure washers in top condition and ensuring reliable performance for years to come.